Blister Trays

- Blister trays are also called plastic inner trays.

- The blister process is used to make hard plastic sheets into plastic with specific grooves. The products are placed in the grooves to protect and beautify the products. The center panels of the trays are designed to Folding can save 50% of storage space compared with traditional packaging.

- There are also transport-type pallet packaging, and pallets are mostly used for convenience.

Blister Trays Common Types

Flocking Trays

Seedling Tray & Plastic Saucer

ESD Trays

Packaging Insert

Free design and free samples, create more packaging possibilities for you.

Flocking Trays

The ordinary plastic hard film surface attached to a layer of velvet material. Normally use for red wine packaging, cosmetic packaging and some of electronic accessories packaging.

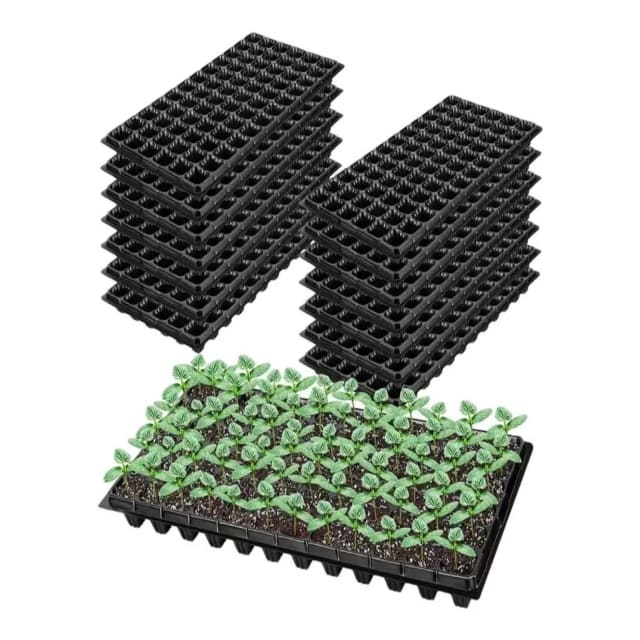

Seedling Tray & Plastic Saucer

Plastic Seedling Tray is a tray specially designed for the planting of seedlings. Individual slots help you use space efficiently by separating seeds while allowing you to plant as close to each other as possible.

Various specifications can be customized.

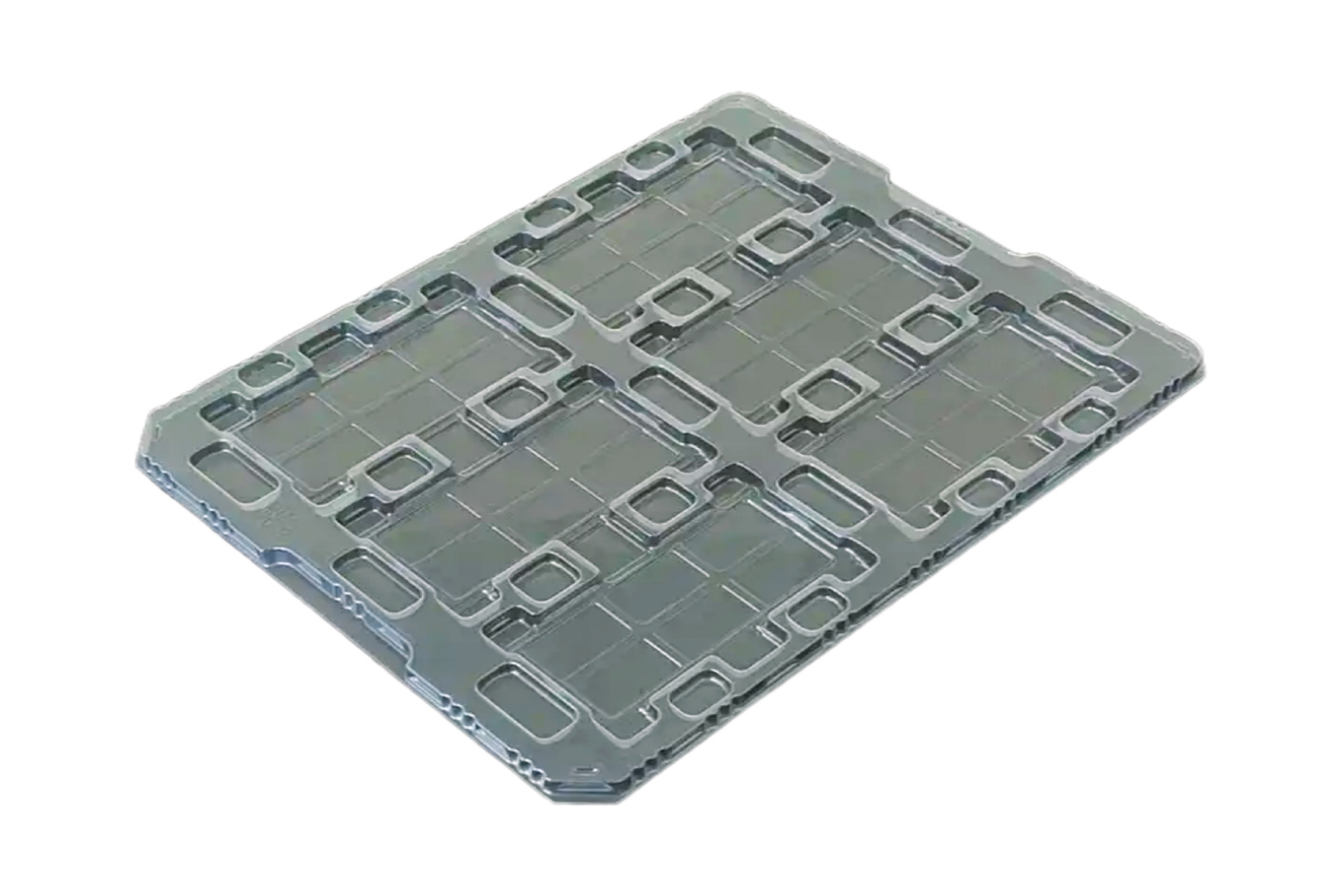

ESD Trays

ESD tray is also called Anti-static tray, which is a special blister packaging material made of PP or PET.

Packaging Insert

The most common type of blister packaging, widely used in the packaging of electronics, electrical appliances, ampoules bottle, cosmetics, stationery, and the packaging of toys.